YesTech Europe

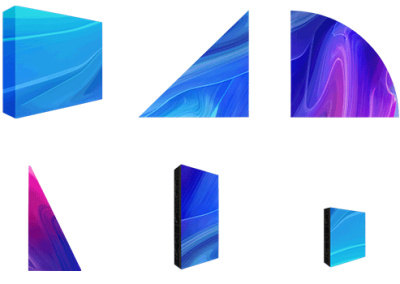

YesTech Europe – Expromo distributor is a professional LED Display Manufacturer. Expromo is the European distributor of Yestechs impeccable and creative Rental and Staging LED displays. Our products have been sold to over 100 countries and regions so far.

Phone number: +45 87 45 80 29

Email: info@expromo.eu